If you’ve ever driven through the Greek countryside in early fall, you’ve probably seen olive mills at work. In fact, you may have even smelled them. That’s because the waste product of the oil-making process – the olive pulp and pits – usually comes down a chute and accumulates behind the mills in large brown mounds that give off earthy smells as they decompose.

For Christos Ververis and Irene Moutsogiannis, those steaming, pungent piles of organic waste hold the secret to a more innovative and sustainable future of material design. After returning to their homes in Lesvos where they spent most of last year’s lockdown, the two friends wanted to give back to their local community. In the spirit of the pandemic, they focused on building something that would celebrate the local heritage in a positive and sustainable way.

© koukosdelab.com

© koukosdelab.com

The entrepreneurial duo chose the simple but iconic bench that traditionally offered respite in most of the island’s public squares, cafes and churches. And to build it, Ververis and Moutsogiannis engineered a material using the island’s commonest industrial by-product: olive pits.

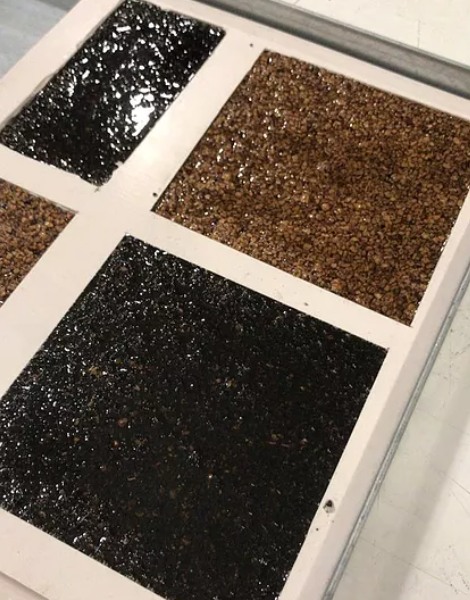

This new eco-material, dubbed “koukoutsi,” is the primary focus of the Koukos de Lab where Ververis and Moutsogianni are transforming bio-waste from the island’s abundant olive mills into a wood-like material that can be used to make furniture, tiles, large surfaces and other objects. The process is rather straightforward: the olive pits are ground into a powder and mixed with plant-based binders, creating a paste that can be molded into almost any shape and texture. The finished product, which can either be blonde or dark brown in color, is as durable as wood.

© koukosdelab.com

While the operation is still small, its founders are dreaming big. The team’s first creation, the bench, was accepted with open arms by the local community and even featured in this year’s London Design Biennale as part of the “Design in an Age of Crisis” initiative. However, the team at Koukos de Lab is now experimenting with different production methods to find more applications for their material.

“The biggest challenge is making it 100% sustainable,” Ververis told Greece Is, “which is what our research is geared towards right now.” While the product is already between 90-95% sustainable, its creation still requires some energy and the binders used are also partly synthetic.

In the coming years, Koukos de Lab hopes to scale up their operation both practically and conceptually. “As communities are aiming for more circular economies,” said Moutsogianni,“we need to reconsider the usefulness of all raw materials available to us and get in touch with our local environments much like our prehistoric ancestors did.”

With this goal in mind, Koukos de Lab eventually wants to become a “lab of ideas” where people can experiment with all kinds of eco-materials and work on creating the building blocks of the future.